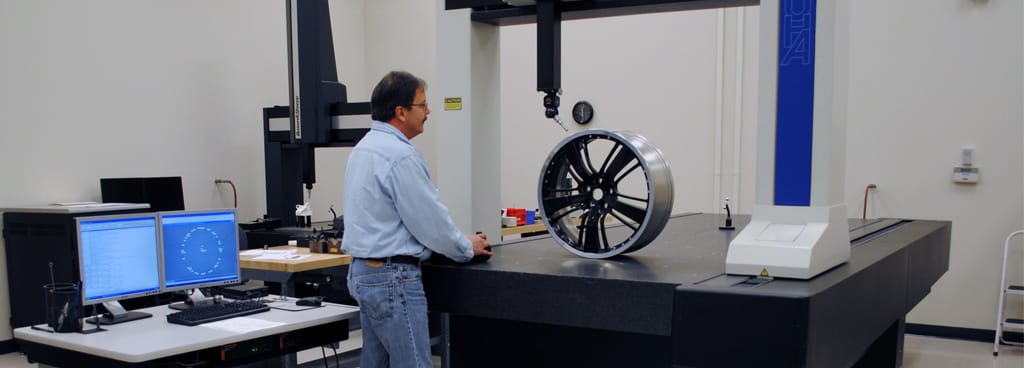

Take the guesswork out of quality assessments with CMM dimensional inspections from ENI Labs. Our GD&T professionals are more than qualified to operate these sophisticated machines in our temperature-controlled A2LA-accredited (Cert. #2147.01) lab.

CMMs quickly collect data with greater precision than most metrological tools. Our machines use contact and non-contact probes to quickly collect hundreds of data points for a computer-generated model of the product. Clients can use the model to compare products with CAD designs and the manufacturer’s specifications.

CMM scans are an irreplaceable tool for several major processes:

- First article inspections

- Compliance checks

- Quality control

- Reverse engineering

Measurements

Our equipment uses touch probes to measure the dimensions of rigid products and non-contact probes for scanning delicate components. We can operate CMM equipment to measure a product’s dimensions and surface characteristics, including:

- Height, length, and width

- Surface roughness

- Shape profiles

- Contour analysis

- Position

- Form

- Thickness and uniformity

- Angles, parallelism, and perpendicularity

Services

- CMM inspection

- Optical CMM inspection

- Non-contact CMM inspection

- 3D white light scanning

- DCC-CMM automation

- Scan to CAD comparison

- Surface analysis

We work with clients to develop a service plan that delivers on your needs and timeline. ENI Labs offers industry-leading turnaround rates with our 1-2 day rush plans, 3-5 day expedited services, and standard 6-15 day turnaround rate.

Call +1(260) 305-1785 or submit a request form for CMM services from ENI Labs.